Mining Solutions

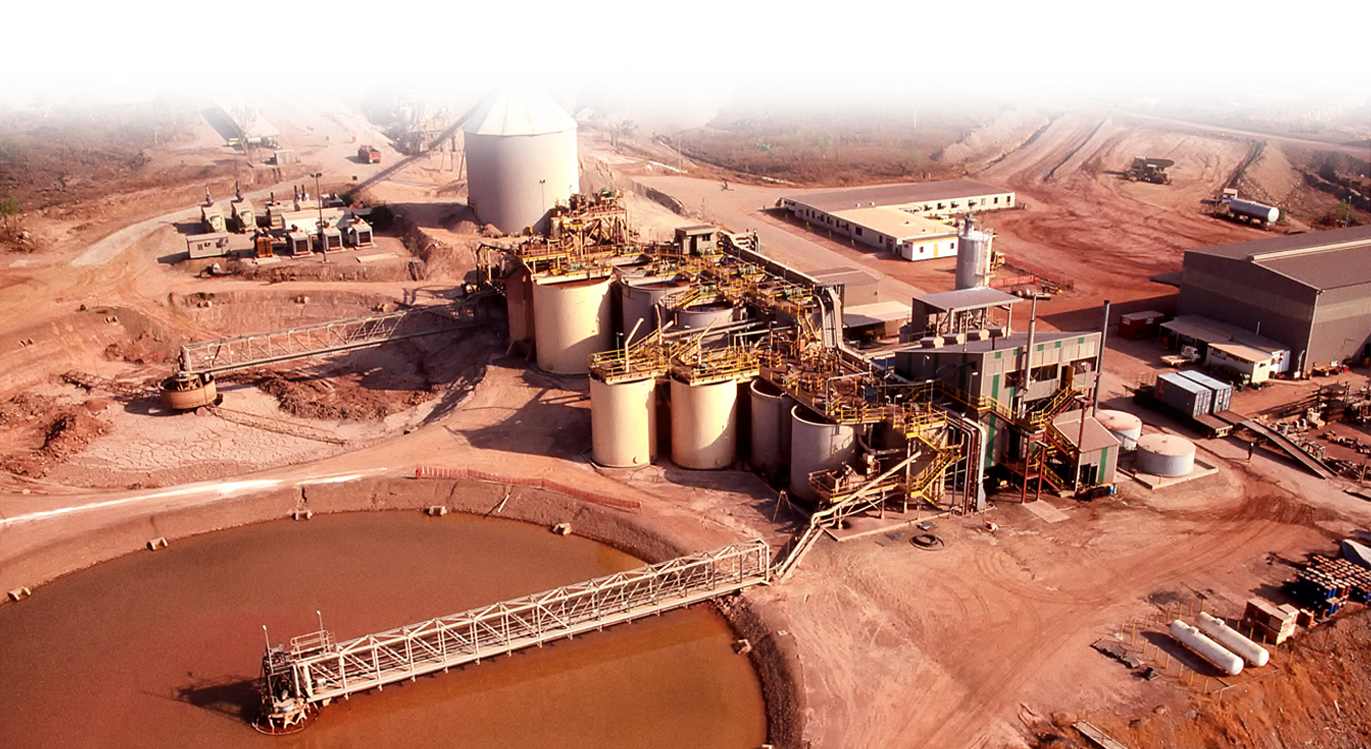

Enhance safety, efficiency, and environmental stewardship in mining. From block cave monitoring to mineral exploration and beyond, discover how ONYX™ peta Distributed Fiber Optic Sensing (DFOS) can transform operations and protect sites through advanced data acquisition and analysis.

Mining

Monitoring

Enhance safety, efficiency, and environmental stewardship in mining. From block cave monitoring to mineral exploration and beyond, discover how ONYX™ peta Distributed Fiber Optic Sensing (DFOS) can transform operations and protect sites through advanced data acquisition and analysis.

ONYX™ Distributed Fiber Optic Sensing (DFOS) technologies, including Distributed Acoustic Sensing (DAS), Distributed Strain Sensing (DSS) and Distributed Temperature Sensing (DTS) are revolutionizing geotechnical monitoring, providing persistent, real-time, long range and gapless monitoring in both open pit and underground mines at significantly lower costs.

Industry-Leading Performance

ONYX™ Sensing Units provide the most accurate and scalable data acquisition solutions for mining applications. Available in ONYX™ nano, ONYX™ peta, and ONYX™ peta EX variants, each unit is optimized for specific operational ranges, performance levels, and environments, with operational ranges spanning from ≤10 km to >100 km. Featuring industry-leading noise floors and ultra-low frequency response, ONYX™ sensors ensure precision and reliability across diverse mining applications, seamlessly integrating with other geotechnical instruments for a comprehensive and efficient monitoring system.

Flexible design options for Mining Environments

The Sintela ONYX™ system is designed to convert existing fiber-optic cables into a dense array of vibro-acoustic sensors that detects naturally occurring acoustic and seismic signals. The configuration of deployed fiber across different environments can be optimised for different acquisition scenarios.

Mining Solutions

Rock Mass Response Monitoring

As the mining industry advances, the demand for cutting-edge geotechnical monitoring and instrumentation has never been greater. ONYX™ delivers continuous, real-time insights into rock mass behavior in both open-pit and underground mining operations. With advanced microseismic and strain monitoring, ONYX™ enables early detection of critical geotechnical hazards – such as slope stability, rockburst , abnormal seismic activity, dynamic strain changes and subsidence – helping to enhance safety, minimize downtime, and optimize productivity.

Seismic Hazard Analysis

Seismic Imaging, Tomography

Numerical Model Calibration

Block Cave Monitoring

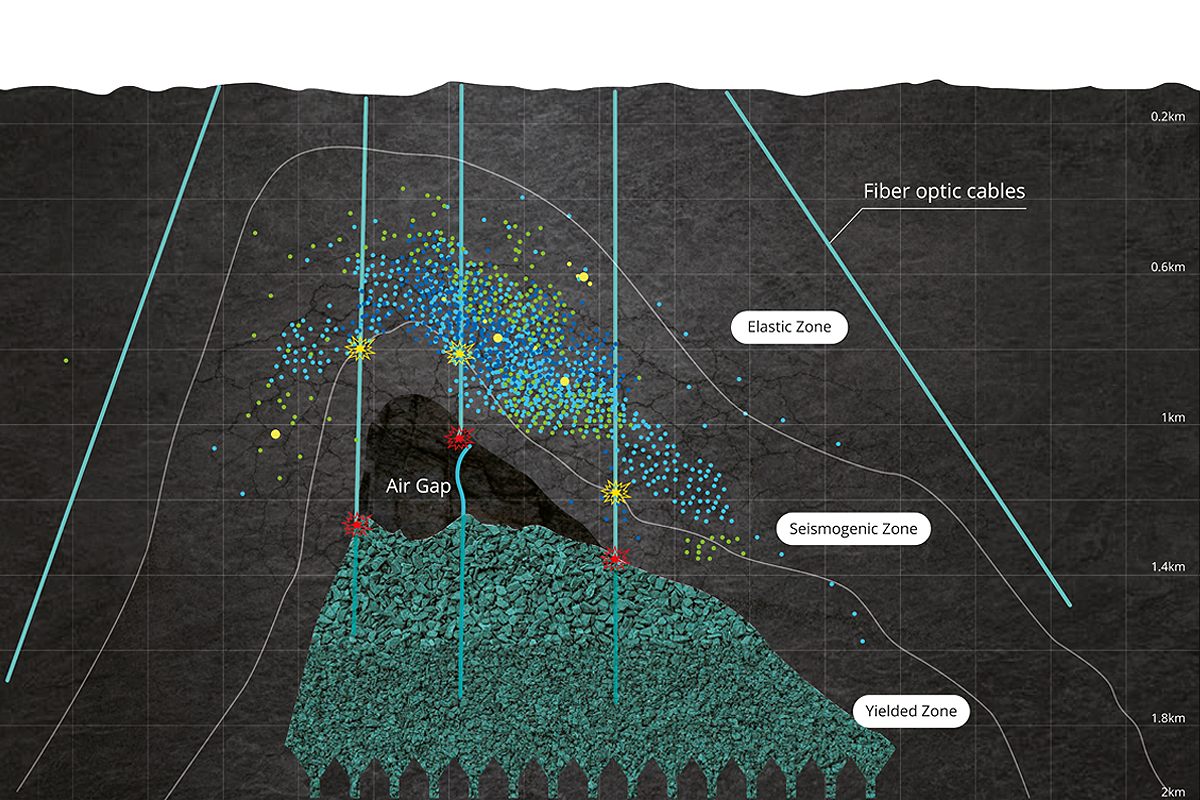

Harnessing the power of Distributed Acoustic Sensing (DAS) and Distributed Strain Sensing (DSS), ONYX™ redefines geotechnical monitoring for modern mining operations. Suitable for block caving, panel caving, and sub-level caving, ONYX™ seamlessly integrates cave back profiling, cave propagation analysis, stress redistribution, microseismic monitoring, and deformation tracking into a single, powerful platform. By accurately identifying yielded, seismogenic and elastic zones, ONYX™ delivers real-time insights that optimize production rate, and drive safer, smarter, and more efficient ore recovery.

Targeted hydraulic fracturing (HF)

Targeted hydraulic fracturing (HF)

Improved draw control

Improved draw control

Reduced risk of rockbursts, air blasts, and mudrushes

Reduced risk of rockbursts, air blasts, and mudrushes

Tailings Dam Monitoring

ONYX™ Distributed Acoustic Sensing (DAS), Distributed Strain Sensing (DSS), and Distributed Temperature Sensing (DTS) offers real-time, continuous monitoring of Tailings Storage Facilities (TSF), transforming the management and preventing failure of these industry critical structures. From the immediate detection of seepage, internal erosion, settlement, and seismic loads to improved geotechnical instrumentation and pore pressure insights. DFOS supports comprehensive dam stability analysis, sub-surface imaging, automated data transmission, and remote monitoring. The integrated DFOS platform reduces the need for frequent inspections, improving environmental monitoring, and compliance with Global Industry Standard on Tailings Management (GISTM).

Remote and web accessed

Remote and web accessed

Real time with customized alert settings

Real time with customized alert settings

Continued monitoring post closure

Continued monitoring post closure

Mineral Exploration

ONYX™ Distributed Acoustic Sensing (DAS) is revolutionising seismic surveys and mineral exploration with high-resolution data through fiber optic cables. This cost-effective technology provides detailed subsurface imaging without the need for traditional geophones and is quick to deploy with low environmental impact. Ideal for Vertical Seismic Profiling (VSP), DAS supports mineral exploration, and resource management by delivering precise insights into subsurface structures and ore deposits. With its broadband response and low noise floor, ONYX™ ensures superior data quality, making it the perfect solution for efficient, sustainable, and accurate mining exploration.

High Spatial Resolution

High Spatial Resolution

Time-Lapse Monitoring

Time-Lapse Monitoring

Minimal Environmental Impact

Minimal Environmental Impact

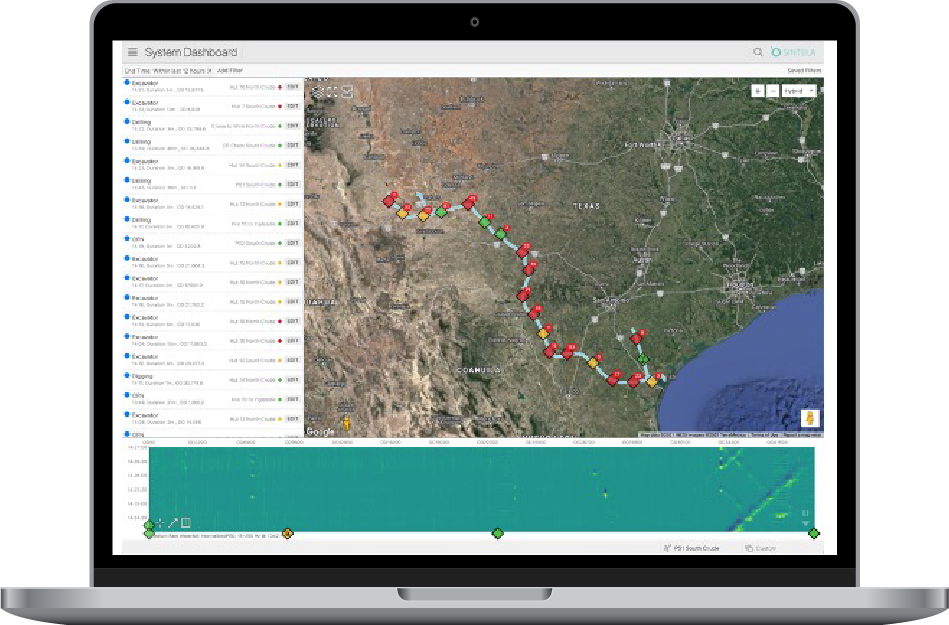

Perimeter Monitoring

Whatever the size or environment, protect critical mining infrastructure against breaches with round-the-clock, real time fiber perimeter intrusion protection system (PIDS) that can be fence-mounted, buried or deployed in a wall top. ONYX™ uses advanced Distributed Acoustic Sensing (DAS) technology, to collect and analyse real-time, quantitative data to identify active intrusions. It integrates seamlessly into existing security systems such as Video Management Systems (VMS), IP Cameras and Radar Devices, delivering 100% positive detections with zero nuisance alarms.

ONYX™ nano up to 10km per unit

ONYX™ peta up to 100km per unit

Operates in harsh environments and temperatures

Operates in harsh environments and temperatures

Conveyor Belt Monitoring

By embedding or attaching fiber optic cables along the length of the conveyor structure, DFOS enables continuous measurement of strain, temperature, and vibration with high spatial resolution. This allows operators to detect anomalies such as belt misalignment, mechanical wear, or structural fatigue before they escalate into costly failures. Additionally, DFOS can identify localized hotspots caused by friction or motor issues, enhancing fire prevention and operational safety. The system can monitor extensive conveyor networks in remote or underground environments, supporting predictive maintenance and reducing downtime.

ONYX™ nano up to 10km per unit

ONYX™ peta up to 100km per unit

Real time with customized alert settings

Real time with customized alert settings

Pipeline Monitoring

DFOS enables continuous monitoring of mining pipelines by detecting strain, temperature changes, and vibrations along their entire length. This allows for early identification of leaks, ground movement, structural stress, or unauthorized access helping prevent failures, optimize maintenance and enhance security. Its long-range coverage and high sensitivity make DFOS ideal for remote or buried pipelines in harsh mining environments.

Continuous remote and web accessed monitoring

ONYX™ peta up to 100km per unit

Operates in harsh environments and temperatures

Operates in harsh environments and temperatures

-81 dB Rad.Hz-½

Leading sensitivity – SEAFOM results

Cost effective

Suitable for short mining distances with built-in microseismic detection, and low power/low weight.

0.53m

Small spatial and gauge lengths available

Get in touch with Sintela for a quote regarding your bespoke requirements

Quantitative Advantage