Backed up with advanced AI algorithms and ever advancing machine learning, all trained on cross-industry applications. Each unit is preloaded with a library of greater than 1,000,000 hours of real-life data providing the highest detection rates with a drastic reduction in nuisance alarms.

This ever-learning life-cycle ensures you get the most out of your system in your environment.

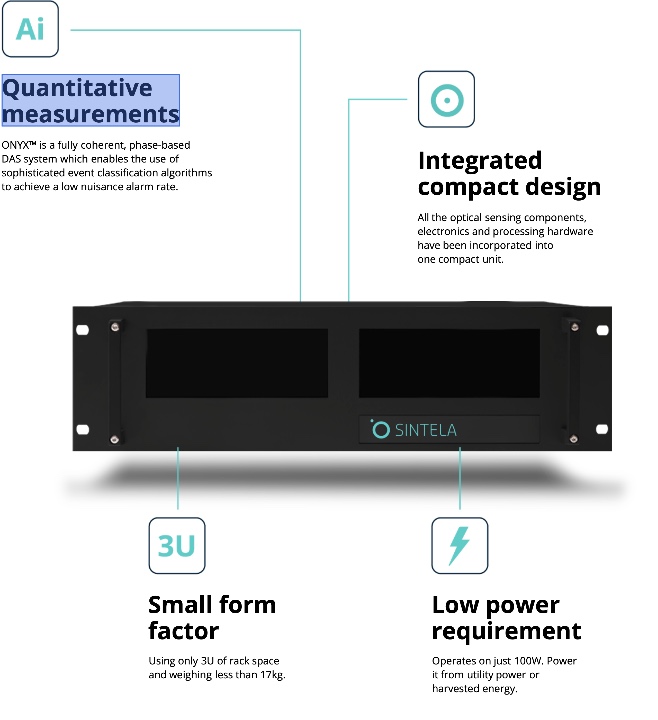

Ai

Hardware

The foundation of the ONYX™ platform

The power and precision you need. Easy to install and maintain.

The ONYX™ Difference

Difficult and costly to install with specialised engineers required to perform installation and commissioning

Easy to install with a built-in setup. Enabling and empowering your team to install and commission each unit

Unable to perform in different environments

Proven to work in all environments. Worldwide deployments in air, sand, soil, snow and sea

High nuisance alarm rates resulting in costly operations

Low nuisance alarms and fully integrated into the concept of operations (CONOPS)

Patchy situational awareness

Full situational awareness

Detection dependent upon weather conditions

Detection immune to weather conditions

Detection of subsurface activity impossible without

additional specialist sensors

Detection of tunnelling activity possible

using buried fiber

The ONYX™ Difference

Multiple fixed platform mounted sensors, requiring significant

operator support

Fewer mobile assets with sensors, resulting in lower operator burden

Large border patrol force

Small border reaction force

Expensive ‘physical denial’ barriers

Lower cost ‘deter & delay’ fences

Patchy situational awareness

Full situational awareness

Detection dependent upon weather conditions

Detection immune to weather conditions

Detection of tunnelling activity impossible without additional specialist sensors

Detection of tunnelling activity possible using buried fiber

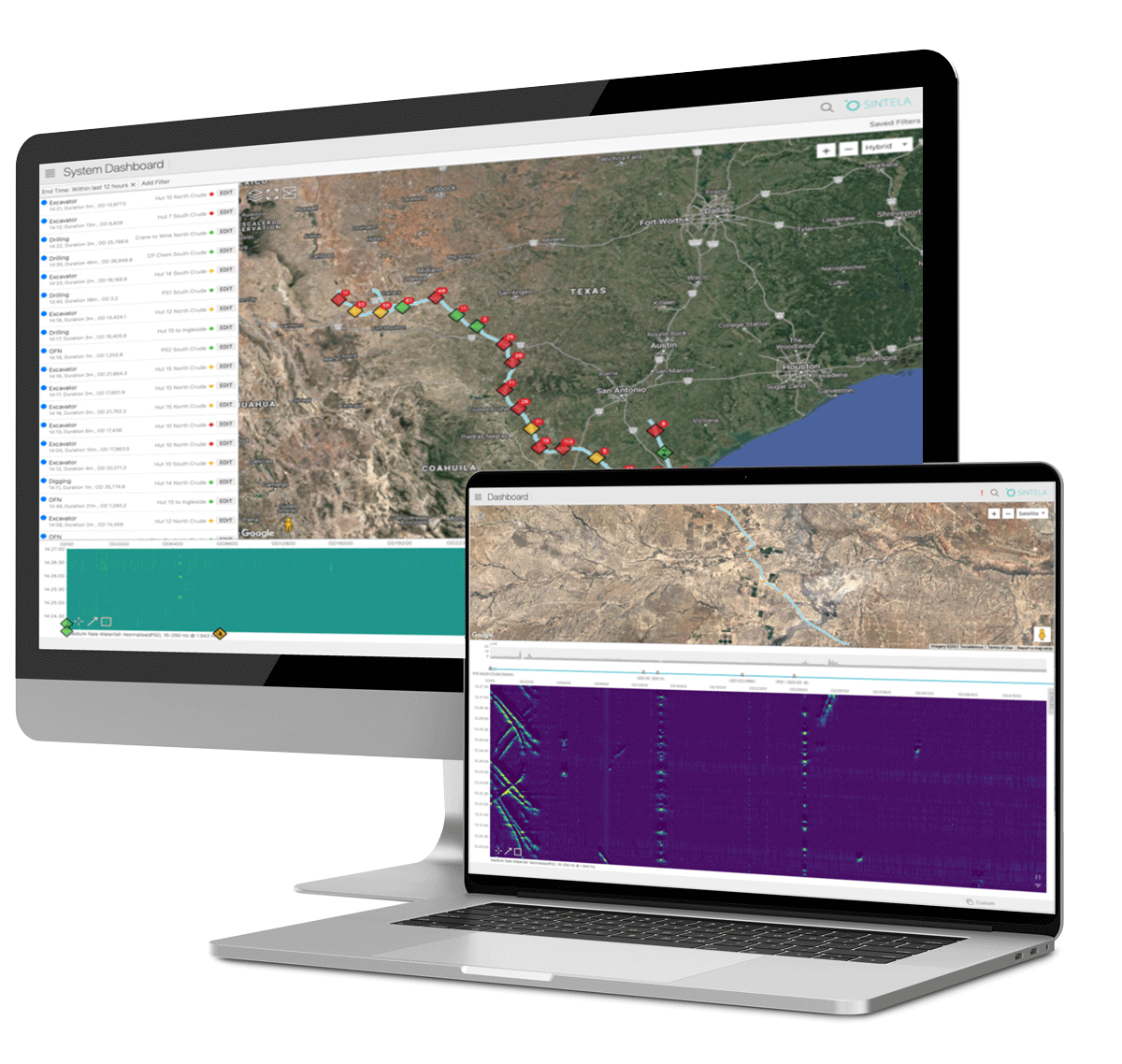

Software

Industry leading bespoke software

Intelligently classify detections in real-time, any time.

Bespoke solutions to extract maximum value from your data. Gain unrivalled insight and power. Deliver transformational change to your infrastructure.

Full software control

Fully automated and optimized for each deployment with software defined acquisition sensing parameters such as pulse width, gauge length, sample rate and decimation factor.

Industry leading algorithms

Application specific detection and classification algorithms pre-loaded with hours of learning providing unrivalled levels of detection with low rates of nuisance alarm call outs.

Web based user Interface

Each ONYX™ unit incorporates its own web server providing the user with remote access from any browser on a secure intranet / internet connection. Full SAML integration for seamless integration into your organizations single source login.

Distributed architecture

ONYX™ has been designed around a fully distributed architecture eliminating single points-of-failure in multi-system networked deployments.

Auto setup with fiber monitoring

An automated installation process simplifies the setup, commissioning and testing stages of the ONYX™ implementation.

Open architecture

ONYX™ is an open system meaning that a customer can load and operate their own software upon the ONYX™ hardware if they prefer.

The state-of-the-art ONYX™ software provides a user-friendly and intuitive experience, incorporating leading-edge detection and classification algorithms. It delivers meaningful and actionable information tailored to specific applications, effectively lowering the ownership costs of monitored assets. Addressing the unique challenges of each industry client, ONYX™ efficiently resolves issues and optimizes performance.

Copyright © 2025 Sintela. All rights reserved.